-

Get to know PET additives for producing quality bottles

Get to know PET additives for producing quality bottles -

Get to know PET additives for producing quality bottles

Get to know PET additives for producing quality bottles -

Get to know PET additives for producing quality bottles

Get to know PET additives for producing quality bottles

Updated at

2023-07-09 05:23:59

Get to know PET additives for producing quality bottles

Definition of PET additives

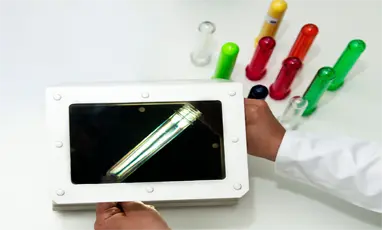

The wide use of additives in this industry (especially pigments) and their impact on the quality of packaging and bottle products requires a brief introduction to the types of additives in this industry

In this section, the additives that may be used during the production of the polymer or in the process of injection and preform formation with PET polymer to achieve specific features or applications are mentioned.

The combination of additive and PET granule, in the preform formation process, should be accompanied by maintaining maximum uniformity and stability in order to create a homogeneous mixture with the polymer, in addition to maintaining the appearance characteristics and uniform distribution of the additive properties, to ensure the quality stability of the product during the process.

How should we choose the right pet additive?

It is recommended to pay attention to the following to choose a suitable additive:

If this additive is used in food packaging, it must have the necessary health approvals for using the product in contact with food.

Make sure the technical data of the supplier and the effectiveness of the additive are correct by performing the necessary tests.

The additive should have the maximum performance in relation to the cost, as well as the necessary stability and quality stability.

For a better combination with polymer, it is better to consider an additive in the base of the polymer. For example, PET-based pigment should be used in the production of colored preforms.

What are the types of polymer additives?

additives are placed in different categories based on their application or other features. Here, without going into the usual classifications, some of these additives are mentioned.

Some of these additives are used in order to protect the packaging plastic or to protect the product inside it from degradation and decomposition in the presence of light, heat and oxygen or other aggressive environmental factors and include stabilizers or absorbers are light and heat and antioxidant agents. Another group of these additives are added to the polymer to improve and control the process (such as process aids, types of lubricants).

The most useful PET additives are those that impart new properties to the polymer, which includes a wide range of additives. Among others, we can mention pigments, nucleating agents, barriers (ultraviolet, gases, etc.) and abductors (oxygen, stadia, etc.):

Pigments

These compounds are used to color the polymer. Usually, for better composition and distribution in the polymer, these pigments are introduced by the masterbatch companies with controlled percentages in the desired polymer base.

In addition to the appearance properties, pigments prevent the entry of some light wavelengths into the product due to the coating and color spectrum and thickness of the film (bottle) and also provide optical protection of the product. Therefore, in choosing the right color, you should pay attention to the nature of the materials that are going to be packed inside the bottle.

UV blockers

Flavor, color and nutrients are more damaged by UV light than color, according to new findings. It has been seen that first vitamins and then color are affected by light.

Vitamins and nutrients are generally sensitive to the effects of temperature, light and oxygen. A slight change in the molecular structure of a food can render it biologically ineffective. There are many vitamins that are particularly vulnerable to UV light. Including: vitamin A, B2 riboflavin, B6, B12 and folic acid.

UV light can reduce both natural and artificial colors in food and beverages, such as those often found in fruits, juices, shampoos, and dishwashing detergents. Natural plant colors such as red, yellow, and orange carotenoid pigments in (fruits, carrots, and tomatoes) and blue and red anthocyanins in berries, cherries, and grapes are unstable to ultraviolet light. Carotenoids such as lutein and beta-carotene tend to lose color when exposed to UV light. Colors used to enhance the appearance of beverages such as soda, juice, and other beverages can be faded by visible and UV light. The presence of vitamin C as an antioxidant or metals in small amounts can speed up this process.

Ultraviolet light accelerates the oxidation of fatty acids to produce unpleasant flavors and odors (even in very low concentrations such as low-fat milk).

UV blocking technology alone and in combination with some pigments (while maintaining the transparency feature in the packaging) is considered a favorable protection for a wide range of food products.

Gas barriers

This type of additive prevents the penetration of oxygen into the bottle or the release of carbon dioxide from the bottle during the useful life of the products, which helps to maintain freshness and increase their shelf life, which can be used in the packaging of fruit juice, carbonated drinks, beer and oxygen-sensitive drinks.

Acetaldehyde scavenger

Acetaldehyde migration in PET containers can have an adverse effect on the quality of products such as mineral water. This additive can be a reliable solution to reduce and control acetaldehyde levels.

Other additives

Nucleation agents and nano compounds are among the additives that can be used to increase efficiency (increase thermal resistance), bottle drinks or food that are hot filled or need to be pasteurized.

New technologies in the packaging industry are developing rapidly. Technologies such as nano particles, nano composites, smart sensors, etc. have increased the desirable capabilities in packaging.

Extending the shelf life of food, creating properties such as environmental compatibility (controlled degradation or faster degradation) are examples of these improved properties.