-

What is IML? IML in the production of plastic containers

What is IML? IML in the production of plastic containers -

What is IML? IML in the production of plastic containers

What is IML? IML in the production of plastic containers -

What is IML? IML in the production of plastic containers

What is IML? IML in the production of plastic containers

Updated at

2023-08-12 14:32:07

What is IML? IML in the production of plastic containers

Today, marketing is an inseparable and important principle in every profession and business and competitive production. If it is done in the right way, it will increase the customer's attention and as a result, the brand will be better known and more sales.

Due to the competitiveness of the markets in recent years, this matter has received more attention and welcome. So that in the industry of producing plastic containers and packaging, appearance attractiveness is important along with quality, and it even leads to surpassing in the competition with other similar industries.

Using IML labeling is one of the most economical and suitable ways to produce plastic containers.

In the old methods for advertising and product recognition, labeling was used by pasting labels on containers, which had other disadvantages in addition to spending a lot of money and time. Now that type of labeling in large industries and businesses has been replaced by the modern labeling method called IML.

Of course, smaller businesses still use the same old method of sticking labels on goods or packaging.

In advanced methods that are carried out using automatic devices, the name of the company or brand is engraved on the containers using various colors in stylish designs, so that the label and the container become one and become two inseparable components of the final product. .

The engraving of the label on the container creates a great visual appeal for the customer due to the high quality of the color and design.

To better understand this article, we need to know about IML and how to use it and its benefits.

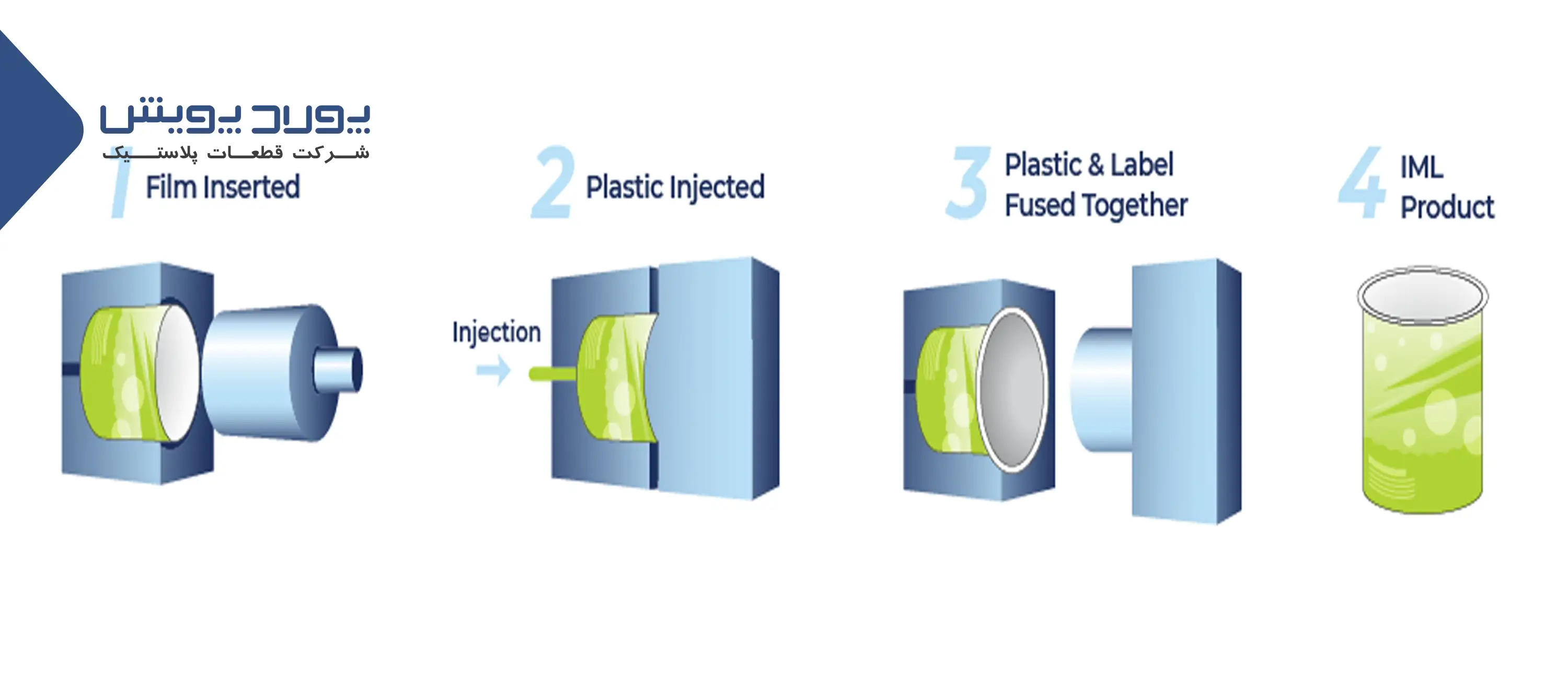

Definition of IML and how to use it

IML stands for In Mold Labeling and is a type of in-mold labeling method, in which a pre-prepared decorative film is placed inside the mold. Plastic balls or resin are heated, and at the same time as the product is formed in the mold, the label, which has the same materials as the container itself, is integrated with it and becomes one with the product.

In 1980, IML was first used in North America for the production of detergent bottles, after which it was gradually used for the production of packaging containers in the food industry following the acceptance of customers and the creation of popularity among industrialists. Today, no restrictions can be placed on its use in the packaging industry.

Combining the label with the product forms a final product, and the label is considered an inseparable part of the product.

This type of labeling is usually suitable for thin-walled packages that do not have a long shelf life.

Food industry companies, packaging of detergents, cosmetics, etc. are among the businesses that use IML.

Production methods of plastic containers with IML printing

Plastic containers are produced by IML printing in two ways.

1) Injection molding

2) Blow Molding

Injection molding process

In this method, the label is placed inside the mold before the material is melted, and at the same time as the product is produced, it is integrated with it and becomes part of the product.

Blow Molding

It is similar to glass blowing, the label is inserted into the mold before being combined with the plastic, but instead of injecting the plastic, air is blown into the desired shape and then stuck to the container.

What are the advantages of the IML labeling method?

High resolution images are produced using a wide range of colors.

In design, it gives business owners the option of powerful and creative graphic designs.

Due to the combination with plastic, it gives a clean and integrated appearance to the container, which was not the case in the old method.

The label remains healthy throughout its life and does not come off the container, and because it is anti-scratch and anti-impact, it maintains its beauty and clean appearance.

It is resistant to washing and water, and in this sense, it has become a reliable method that can easily be maintained in humid environments and extreme temperature fluctuations.

Also, this labeling method is resistant to wear and penetration of chemicals.

Since the label printed on the packaging is made of the same material as the production container, it is suitable for recycling and is compatible with the environment.

Due to the integration of the production stage with labeling, the in-mold labeling method has shortened the production and preparation cycle and is cost-effective compared to the PML method. Because it does not require manpower and enough space for labeling.

Is IML suitable for everyone?

Despite the many advantages of IML that have been mentioned and the lack of restrictions in its use for many businesses in the field of food, chemical, detergent and cosmetic packaging, it should be seen whether using this method is suitable for your desired business or not. ?

Pay attention to the following points:

Minimum order quantity is high

The minimum order quantity for IML is higher compared to the old methods due to the cost of setting up the device with precise positioning.

For some businesses, this method is very valuable because the cost of producing each container is lower in warehouse production.

Increased delivery time:

Because the use of IML requires more time for the design and specific format, the production time to the final completion is longer.

The types of materials used to make containers and labels are polyethylene and polypropylene.

Application of in-format tagging

In hygiene products such as detergents

Food packaging such as yogurt container, milk, confectioneries, etc.

Cosmetic

And...

Poolad Pooyesh Company is one of the large and advanced companies that uses this labeling method to produce its products using modern equipment.